Residential Hydronic

Specialty & Made-to-Order Radiators

Overview

Runtal Specialty Radiators may be fabricated to match all of your architectural and aesthetic needs. Curved radiators, segmented radiators for bay windows and high-output double panels can be custom made. Column Radiators and our exclusive Hot Spring and Flow Form Designs offer one of a kind custom design and architecture. Please visit our Design Assistance and Custom Products page, or give us a call at 1-800-526-2621 with your special needs. Providing a unique heating solution is a specialty of ours.

Styles

Runtal Specialty Radiators may be fabricated to match all of your architectural and aesthetic needs. Curved radiators, segmented radiators for bay windows and high-output double panels can be custom made. Please contact Runtal with your special needs. Providing a unique heating solution is our specialty.

Made-to-Order Baseboard

Made-to-Order Wall Panels

Made-to-Order Vertical Panels

Runtal’s Vertical Panels are ideal for situations where floor space is limited such as entryways and kitchens. They are often found mounted behind a door or on a column.

Runtal can craft a perfect solution to fit your exact design or heat requirements with heights available from 20 to 354 inches (in 2” increments). Additional widths (up to 24 tubes or 69-3/4” wide) are also available upon request.

Column Radiators

Runtal’s Column Radiators are an ideal solution where the view in is as important as the view out. Where the design calls for floor to ceiling glass, column radiators may be pedestal mounted in front of the glass without obstructing the view. Column radiators may also be used as room dividers or balustrade. They may be either wall mounted, or pedestal mounted.

Curved & Segmented Radiators

Curved radiators, segmented radiators for bay windows and high-output double panels can be custom made. Please contact Runtal with your special needs. Providing a unique heating solution is a specialty.

High Output Radiators

High Output radiators provide answers for large window wall applications and entry ways where extra heat is needed, however space is limited. The Double panel/double fin or triple fin design provides roughly 2 to 2.5 times the heat output of our standard baseboard product.

Hot Spring Radiators

Brilliantly imaginative, the mesmerizing and stylish design of the Hot Spring captures a tightly coiled elegance in reflected light.

Flow Form Radiators

The industrial heating elements of the Flow Form appear as a beautiful object in its own right. The spiral fins add a dramatic twist to modern design.

Made-to-Order Baseboard

Overview

• Ideal where a low profile is desired

• Easy replacement for fin-tube or cast iron radiators

• Available from 20 inches to 29-1/2 feet in length

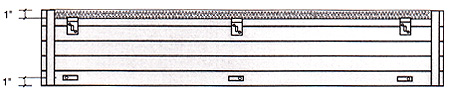

Runtal’s baseboard (made to order) is available in 1 to 4 tube heights. It may be manufactured in lengths from 20 inches to 29-1/2 feet long in increments of 2 inches. Ten standard colors as well as an array of designer colors are available. Runtal’s baseboard style is perfect for situations where sheet metal-covered fin-tube or cast iron is being replaced. In these cases, it is often easiest to use the existing piping and simply order the appropriate lengths.

|

|

||||

| Model: Height: Heat Output: per Foot* |

VLX7/7 2.8″ 2″ 380 BTUH/ft.* |

VLX14/14 5.7″ 2″ 600 BTUH/ft.* |

VLX21/21 8.6″ 2″ 770 BTUH/ft.* |

VLX28/28 11.5″ 2″ 930 BTUH/ft.* |

*Outputs shown are figured at 180°F

Operation & Maintenance

Hydronic Radiator Operation

- Radiators are manufactured in the USA of cold rolled low carbon steel and should be used only in closed closed hydronic systems to assure no corrosion of any system components.

- Proper radiator operation depends on adequate flow of water to the panel, which can only be accomplished when all the system air has been fully vented from the panels.

- Radiators should each be vented, with the system pressurized but in a static state (pumps off). Venting may need to be done periodically to assure a closed system.

- DO NOT OVER-PRESSURIZE RADIATORS:

Most radiators are standard pressure construction. Standard pressure radiators should be tested with NO MORE THAN 50 PSI. - Radiator Operating Pressure Ratings:

Standard Pressure – 56 psi max (Tested at 74 psi)

High Pressure – 128 psi max (Tested at 184 psi) - Radiators expand a maximum of 0.016 inch per linear foot of length if heated to 215°F. Piping attached to the radiator must provide the necessary expansion compensation.

- Flexible piping and elbowed piping are two simple ways to provide the 1/8 inch to 1/2 inch (typical) of flexibility required in expansion situations (usually series piping).

- Runtal Radiators require less flow rate than other hydronic heating products. If flow noise is apparent, balance the system until the noise is reduced.

- For a delta T of 20°F. (T supply minus T return), divide the total Btu/hr capacity of the loop by 10,000. This gives the Flow Rate in gallons per minute (GPM)

- Many levels of control are available today for hydronic systems. Runtal Radiators will provide nice, even heating whether operated by a simple thermostat to baseboard loop system, or an advanced boiler reset controller with motorized mixing valves, constant circulation and 2-pipe distribution.

Radiator Maintenance

- Hydronic system maintenance should include routine checks for piping leaks (usually indicated by frequent makeup water), and a yearly diagnosis of the system water pH to evaluate its corrosive potential.

- Internal radiator maintenance depends entirely on the system water makeup and proper venting. Hydronic system additives are available to passivate and protect against freezing. These additives will not significantly reduce the output of Runtal Radiators.

- External radiator maintenance consists of keeping the surfaces clean, and any paint nicks or deep scratches painted with touch-up to prevent any surface rust.

- Radiators can be painted after sanding with fine grit paper to dull the high gloss and by wiping with solvent or a tack rag. Use only oil-based enamel paint (alkyd, acrylic, urethane, epoxy) – do not use latex or lacquer paint. Use urethane or epoxy enamel for radiators located in harsh environments. Spray the paint to achieve an even coating, and let dry completely before heating the radiator.

Made-to-Order Wall Panels

Overview

• Perfect replacement for cast iron radiators

• Ideal under windows–allows curtains to hang to the floor

• Allows more flexible furniture placement

Runtal’s wall panel style radiators are ideal for placement under windows or on walls where floor space is at a premium. When placed under windows, wall panels help eliminate cold spots and drafts, while allowing curtains to hang naturally to the floor. Simply choose the height and length that best suits your design and output requirements. Wall panels are available in lengths 20 inches to 29-1/2 feet in increments of 2 inches. Ten standard colors as well as an array of designer colors are available.

Wall panel radiators are available with or without fins. When hung, the radiators have the same appearance, however the addition of fins increases the output of the panels.

|

|

|||||

|

Available from 20 inches to 29-1/2 feet in width |

|||||

| With Fins | Without Fins | |||||

| Number of Tubes |

Height | Depth | Model Number |

Heat Output* per ft. |

Model Number |

Heat Output* per ft. |

| 5 | 14.4″ | 2″ | VLX35/35 | 1240 BTUH | VX35 | 700 BTUH |

| 6 | 17.3″ | 2″ | VLX42/42 | 1430 BTUH | VX42 | 840 BTUH |

| 7 | 20.2″ | 2″ | VLX49/49 | 1620 BTUH | VX49 | 990 BTUH |

| 8 | 23.1″ | 2″ | VLX56/56 | 1810 BTUH | VX56 | 1130 BTUH |

| 9 | 26.1″ | 2″ | VLX63/56 | 1890 BTUH | VX63 | 1280 BTUH |

| 10 | 29″ | 2″ | VLX70/56 | 2020 BTUH | VX70 | 1420 BTUH |

*Outputs shown are figured at 180°F

Operation & Maintenance

Hydronic Radiator Operation

- Radiators are manufactured in the USA of cold rolled low carbon steel and should be used only in closed closed hydronic systems to assure no corrosion of any system components.

- Proper radiator operation depends on adequate flow of water to the panel, which can only be accomplished when all the system air has been fully vented from the panels.

- Radiators should each be vented, with the system pressurized but in a static state (pumps off). Venting may need to be done periodically to assure a closed system.

- DO NOT OVER-PRESSURIZE RADIATORS:

Most radiators are standard pressure construction. Standard pressure radiators should be tested with NO MORE THAN 50 PSI. - Radiator Operating Pressure Ratings:

Standard Pressure – 56 psi max (Tested at 74 psi)

High Pressure – 128 psi max (Tested at 184 psi) - Radiators expand a maximum of 0.016 inch per linear foot of length if heated to 215°F. Piping attached to the radiator must provide the necessary expansion compensation.

- Flexible piping and elbowed piping are two simple ways to provide the 1/8 inch to 1/2 inch (typical) of flexibility required in expansion situations (usually series piping).

- Runtal Radiators require less flow rate than other hydronic heating products. If flow noise is apparent, balance the system until the noise is reduced.

- For a delta T of 20°F. (T supply minus T return), divide the total Btu/hr capacity of the loop by 10,000. This gives the Flow Rate in gallons per minute (GPM)

- Many levels of control are available today for hydronic systems. Runtal Radiators will provide nice, even heating whether operated by a simple thermostat to baseboard loop system, or an advanced boiler reset controller with motorized mixing valves, constant circulation and 2-pipe distribution.

Radiator Maintenance

- Hydronic system maintenance should include routine checks for piping leaks (usually indicated by frequent makeup water), and a yearly diagnosis of the system water pH to evaluate its corrosive potential.

- Internal radiator maintenance depends entirely on the system water makeup and proper venting. Hydronic system additives are available to passivate and protect against freezing. These additives will not significantly reduce the output of Runtal Radiators.

- External radiator maintenance consists of keeping the surfaces clean, and any paint nicks or deep scratches painted with touch-up to prevent any surface rust.

- Radiators can be painted after sanding with fine grit paper to dull the high gloss and by wiping with solvent or a tack rag. Use only oil-based enamel paint (alkyd, acrylic, urethane, epoxy) – do not use latex or lacquer paint. Use urethane or epoxy enamel for radiators located in harsh environments. Spray the paint to achieve an even coating, and let dry completely before heating the radiator.

Made-to-Order Vertical Panels

Overview

• Provides heat where floor space is limited

• Ideal for entryways and kitchens

|

|

|

||||||||

|

Available from 20 inches to 29-1/2 feet in height |

|||||||||

| Number of Tubes |

Model Number |

Width | Depth | Heat Output* per ft |

| 1 | HX7 | 2.7″ | 2″ | 140 BTUH |

| 2 | HX14 | 5.7″ | 2″ | 280 BTUH |

| 3 | HX21 | 8.6″ | 2″ | 420 BTUH |

| 4 | HX28 | 11.5″ | 2″ | 560 BTUH |

| 5 | HX35 | 14.3″ | 2″ | 700 BTUH |

| 6 | HX42 | 17.3″ | 2″ | 840 BTUH |

| 7 | HX49 | 20.3″ | 2″ | 980 BTUH |

| 8 | HX56 | 23.1″ | 2″ | 1120 BTUH |

| 9 | HX63 | 26.1″ | 2″ | 1260 BTUH |

| 10 | HX70 | 29″ | 2″ | 1400 BTUH |

*Outputs shown are figured at 180°F

Operation & Maintenance

Hydronic Radiator Operation

- Radiators are manufactured in the USA of cold rolled low carbon steel and should be used only in closed closed hydronic systems to assure no corrosion of any system components.

- Proper radiator operation depends on adequate flow of water to the panel, which can only be accomplished when all the system air has been fully vented from the panels.

- Radiators should each be vented, with the system pressurized but in a static state (pumps off). Venting may need to be done periodically to assure a closed system.

- DO NOT OVER-PRESSURIZE RADIATORS:

Most radiators are standard pressure construction. Standard pressure radiators should be tested with NO MORE THAN 50 PSI. - Radiator Operating Pressure Ratings:

Standard Pressure – 56 psi max (Tested at 74 psi)

High Pressure – 128 psi max (Tested at 184 psi) - Radiators expand a maximum of 0.016 inch per linear foot of length if heated to 215°F. Piping attached to the radiator must provide the necessary expansion compensation.

- Flexible piping and elbowed piping are two simple ways to provide the 1/8 inch to 1/2 inch (typical) of flexibility required in expansion situations (usually series piping).

- Runtal Radiators require less flow rate than other hydronic heating products. If flow noise is apparent, balance the system until the noise is reduced.

- For a delta T of 20°F. (T supply minus T return), divide the total Btu/hr capacity of the loop by 10,000. This gives the Flow Rate in gallons per minute (GPM)

- Many levels of control are available today for hydronic systems. Runtal Radiators will provide nice, even heating whether operated by a simple thermostat to baseboard loop system, or an advanced boiler reset controller with motorized mixing valves, constant circulation and 2-pipe distribution.

Radiator Maintenance

- Hydronic system maintenance should include routine checks for piping leaks (usually indicated by frequent makeup water), and a yearly diagnosis of the system water pH to evaluate its corrosive potential.

- Internal radiator maintenance depends entirely on the system water makeup and proper venting. Hydronic system additives are available to passivate and protect against freezing. These additives will not significantly reduce the output of Runtal Radiators.

- External radiator maintenance consists of keeping the surfaces clean, and any paint nicks or deep scratches painted with touch-up to prevent any surface rust.

- Radiators can be painted after sanding with fine grit paper to dull the high gloss and by wiping with solvent or a tack rag. Use only oil-based enamel paint (alkyd, acrylic, urethane, epoxy) – do not use latex or lacquer paint. Use urethane or epoxy enamel for radiators located in harsh environments. Spray the paint to achieve an even coating, and let dry completely before heating the radiator.

Design & Color Options

With a vibrant and varied palette, you can choose a shade that will blend into the background or add an eye-catching focal point to your room. Whether you’re decorating a neutral space, or you’re eager to inject character and color, there’s an ideal match for you.

You can choose from a range of standard colors or pay a little extra for a custom shade for your home. For custom color options please visit our Design Assistance and Custom Products Section where our team can help you find the exact match you are looking for.

Column Radiators

Overview

• Ideal for floor-to-ceiling applications

• May be used as balustrade or knee-wall

Runtal column radiators are ideal for floor-to-ceiling applications and may also be used as a balustrade or knee-wall. Column radiators allow a view out. They may be either wall-mounted, or pedestal-mounted, away from the wall. They are available in lengths from 6 inches to 20 feet. Ten standard colors as well as an array of designer colors are available.

|

|

|||||

|

Available from 6 inches to 20 feet in length |

|||||

| Model Number |

Height | Depth | Heat Output* per ft |

| R1040-2 | 15.9″ | 4″ | 960 BTUH |

| R1060-2 | 23.6″ | 4″ | 1320 BTUH |

| R1075-2 | 29.5″ | 4″ | 1620 BTUH |

| R1090-2 | 35.6″ | 4″ | 1860 BTUH |

| R1200-2 | 78.8″ | 4″ | 4380 BTUH |

| R1215-2 | 84.6″ | 4″ | 4740 BTUH |

*Outputs shown are figured at 180°F

Operation & Maintenance

Hydronic Radiator Operation

- Radiators are manufactured in the USA of cold rolled low carbon steel and should be used only in closed closed hydronic systems to assure no corrosion of any system components.

- Proper radiator operation depends on adequate flow of water to the panel, which can only be accomplished when all the system air has been fully vented from the panels.

- Radiators should each be vented, with the system pressurized but in a static state (pumps off). Venting may need to be done periodically to assure a closed system.

- DO NOT OVER-PRESSURIZE RADIATORS:

Most radiators are standard pressure construction. Standard pressure radiators should be tested with NO MORE THAN 50 PSI. - Radiator Operating Pressure Ratings:

Standard Pressure – 56 psi max (Tested at 74 psi)

High Pressure – 128 psi max (Tested at 184 psi) - Radiators expand a maximum of 0.016 inch per linear foot of length if heated to 215°F. Piping attached to the radiator must provide the necessary expansion compensation.

- Flexible piping and elbowed piping are two simple ways to provide the 1/8 inch to 1/2 inch (typical) of flexibility required in expansion situations (usually series piping).

- Runtal Radiators require less flow rate than other hydronic heating products. If flow noise is apparent, balance the system until the noise is reduced.

- For a delta T of 20°F. (T supply minus T return), divide the total Btu/hr capacity of the loop by 10,000. This gives the Flow Rate in gallons per minute (GPM)

- Many levels of control are available today for hydronic systems. Runtal Radiators will provide nice, even heating whether operated by a simple thermostat to baseboard loop system, or an advanced boiler reset controller with motorized mixing valves, constant circulation and 2-pipe distribution.

Radiator Maintenance

- Hydronic system maintenance should include routine checks for piping leaks (usually indicated by frequent makeup water), and a yearly diagnosis of the system water pH to evaluate its corrosive potential.

- Internal radiator maintenance depends entirely on the system water makeup and proper venting. Hydronic system additives are available to passivate and protect against freezing. These additives will not significantly reduce the output of Runtal Radiators.

- External radiator maintenance consists of keeping the surfaces clean, and any paint nicks or deep scratches painted with touch-up to prevent any surface rust.

- Radiators can be painted after sanding with fine grit paper to dull the high gloss and by wiping with solvent or a tack rag. Use only oil-based enamel paint (alkyd, acrylic, urethane, epoxy) – do not use latex or lacquer paint. Use urethane or epoxy enamel for radiators located in harsh environments. Spray the paint to achieve an even coating, and let dry completely before heating the radiator.

Curved & Segmented Radiators

Overview

• Integrates into curved wall designs

• One-piece radiator for bay windows

• Template required — contact us for details

For bay windows, or curved structures, accent the architecture with a dramatic curved radiator from Runtal. Template required.

Downloads

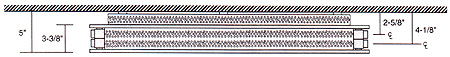

High Output Radiators: Model Type VLX-VX

Heating Capacity

Model Type VLX-VX

BTUH/ft Ratings

VLX-VX-3 with Both Side & Vertical Connections – Shown for Example Only

Technical Data For All VLX-VX Models Is Included Below

| MODEL TYPE |

HEIGHT H |

BTUH/FT OUTPUT @ LISTED AWT & 65°F EAT | DRY WT lbs/ft |

||||||||

| 215°F | 190 | 180 | 170 | 160 | 150 | 140 | 130 | 120 | |||

|

VLX 7/7 – VX7 |

2-3/4″ | 979 | 769 | 689 | 612 | 537 | 465 | 395 | 327 | 263 | 3.6 |

|

VLX 14/14 – VX14 |

5-3/4″ | 1589 | 1247 | 1118 | 993 | 872 | 754 | 640 | 531 | 427 | 6.9 |

|

VLX 21/21 – VX21 |

8-5/8″ | 2019 | 1584 | 1421 | 1261 | 1108 | 958 | 813 | 675 | 542 | 10.1 |

|

VLX 28/28 – VX28 |

11-1/2″ | 2417 | 1897 | 1701 | 1510 | 1326 | 1147 | 974 | 808 | 649 | 13.9 |

|

VLX 35/35 – VX35 |

14-3/8″ | 3094 | 2498 | 2177 | 1933 | 1697 | 1457 | 1246 | 1034 | 831 | 16.8 |

|

VLX 42/42 – VX42 |

17-1/4″ | 3470 | 2723 | 2443 | 2168 | 1904 | 1646 | 1398 | 1160 | 932 | 20.0 |

|

VLX 49/49 – VX49 |

20-1/4″ | 3846 | 3018 | 2707 | 2403 | 2110 | 1824 | 1549 | 1286 | 1033 | 23.5 |

|

VLX 56/56 – VX56 |

23-1/8″ | 4211 | 3304 | 2963 | 2631 | 2310 | 1997 | 1696 | 1408 | 1131 | 27.6 |

|

VLX 63/56 – VX63 |

26-1/8″ | 4432 | 3478 | 3119 | 2769 | 2431 | 2102 | 1785 | 1481 | 1190 | 29.9 |

|

VLX 70/56 – VX70 |

29″ | 4644 | 3645 | 3269 | 2901 | 2548 | 2203 | 1871 | 1552 | 1247 | 32.1 |

NOTE: Heat Outputs for various AWT’s include 15% Heat Effect for placement along outside walls. Use the 215° F Output Rating with the Correction Factor for more specific design conditions. High Pressure increases Dry Weight by 15%

Correction Factors

Correction Factors

| EAT | |||||||||||

| AWT | 45°F | 50°F | 55°F | 60°F | 65°F | 70°F | 75°F | 80°F | 85°F | 90°F | 95°F |

| 240°F | 1.365 | 1.350 | 1.304 | 1.266 | 1.220 | 1.171 | 1.124 | 1.086 | 1.039 | 1 | 0.953 |

| 235°F | 1.343 | 1.305 | 1.267 | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 |

| 230°F | 1.305 | 1.267 | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 |

| 225°F | 1.267 | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 |

| 220°F | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 |

| 215°F | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 |

| 210°F | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 |

| 205°F | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 |

| 200°F | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 |

| 195°F | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 |

| 190°F | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 |

| 185°F | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 |

| 180°F | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 |

| 175°F | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 |

| 170°F | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 |

| 165°F | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 |

| 160°F | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 |

| 155°F | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 |

| 150°F | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 |

| 145°F | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 |

| 140°F | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 |

| 135°F | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 |

| 130°F | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 |

| 125°F | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 |

| 120°F | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 |

| 115°F | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 |

| 110°F | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 | 0.50 |

| 105°F | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 | 0.50 | 0.030 |

| 100°F | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 | 0.50 | 0.030 | 0.011 |

| EXAMPLE: | To find the BTUH/ft Rating for an RF-4 Panel at 145°F AWT and 65°F EAT, Multiply the Correction Factor (0.438) by the BTUH/ft Rating at 215°F (1351), e.g. (0.438) X (1351) = 592 BTUH/ft |

Flow Rates

How To Determine Flow Rates

The flow rate through a Runtal radiator (or series of radiators) is dependent on the length of the radiator (or combined length of the radiator series), and the design Entering Water Temperature (EWT) and the design Leaving Water Temperature (LWT).

The designer picks the design EWT and LWT. For example, he might pick 170°F as the EWT and 150°F as the LWT. The median point between these two temperatures is called the Average Water Temperature (AWT), and in this example the AWT is 160°F.

The Runtal Heating Capacity charts are based on the heating capacity per foot of radiator, based on the designer’s chosen AWT, and this heating capacity per foot is expressed in units of BTUH/FT @ a given AWT. The required flow rate (GPM) is figured as follows:

Flow Rate = (Heating Capacity/Foot X Radiator Length)

DT –LWT) X 500]

The (EWT – LWT) is commonly referred to as the “Delta T”, or “DT”.

Therefore, our Flow Rate formula becomes:

GPM = (BTUH/FT X FT of Radiator) DT (DT X 500)

As an example, let’s say our designer needs 445 BTUH/FT capacity, over a

10′-0″ span of wall, and has chosen the design water temperatures as EWT = 170°F, and LWT = 150°F. This means our AWT is 160°F. Looking in the Runtal type “R” radiator Heating Capacity chart, we see that an R-4 radiator gives us the required 445 BTUH/FT at 160°F AWT. Therefore, the required flow rate for the 10′-0″ long R-4 radiator is:

GPM = (445 BTUH/FT X 10FT) DT (20°F DT X 500) = 0.445 GPM

Note that there are various combinations of EWT and LWT that can result in the same AWT. In our example above, for instance, a 180°F EWT and a 140°F LWT result in the same 160°F AWT. With Runtal’s unique flattened water tube design, Delta T’s of up to 60°F are possible without concern that the flow rate is too low for heat transfer (see the “Design Tips” section for more information).

As for a maximum flow rate for Runtal radiators, we recommend no more that 1.5 GPM per water tube. For our R-4 example above, this would mean a maximum flow rate of 6 GPM for an opposite end piped radiator, or 3 GPM for a same end piped radiator (see the “Design Tips” section for more information).

Piping Options

Piping Options

A Type Connections

|

B Type Connections

|

||||||||||

C Type Connections

|

D Type Connections

|

||||||||||

Opposite End Series

|

|||||||||||

Same End Series

|

|||||||||||

Specifications

|

VLX-VX panel radiators are manufactured in the USA from cold rolled steel, and consist of two panels with two sets of fins. The panels are finished in a gloss powdercoat, and are available in many standard colors and over 100 optional colors. These panels are made in lengths from 2’-0” to 29’-6”, and heights from 3” to 29”. Standard piping connections are 1/2” NPT for inlet and outlet piping, and 1/8” NPT for vents (3/4” NPT inlets and outlets are available by special order). For more complete VLX-VX specifications, please refer to the Runtal technical pages. |

BTUH/ft Ratings

| Energy efficient as well as space saving, VLX-VX panels are both radiant and convective. These panels provide more comfort at a lower room temperature than convective heaters. Various average water temperatures (AWT) are shown here for convenience, but for more specific conditions use the appropriate correction factor with the 215°F rating. Please see the technical pages for the correction factor best suited to the design conditions. |

* 3.4″ depth for pedestal mount radiators |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

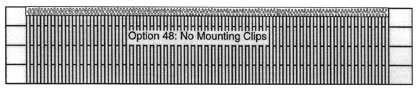

Mounting Systems

VLX 21/21 – VX21 |

Wall mounting with a continuous mounting system (brackets included) is standard on all VLX-VX Panels. Free standing, cantilever and recessed wall mounting systems are also available. Please see the VLX-VX technical pages for more complete mounting details. |

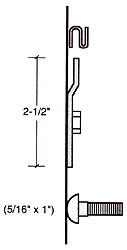

Wall Mounting

Model Type VLX-VX

Wall Mounting

| VLX-VX Models (back view) |

|

|

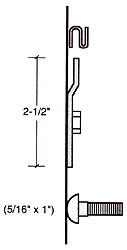

For Radiators |

20″ to 60″ Long – Use 2 K11 Brackets, one at each end |

|

|

62″ to 138″ Long – Use 3 K11 Brackets, one at each end, one at the center |

|

|

140″ to 236″ Long – Use 4 K11 Brackets, one at each end, two distributed evenly in the middle |

| 238″ to 296″ Long – Use 5 K11 Brackets, one at each end, three distributed evenly in the middle | |

| 298″ to 354″ Long – Use 6 K11 Brackets, one at each end, four distributed evenly in the middle |

|

|

|

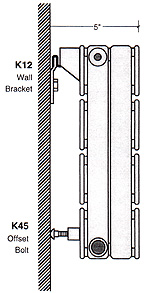

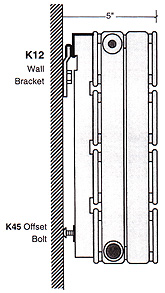

R clip – Mount to the grille back on the R Radiator at the K12 Positions K12 Wall Bracket – Support Bracket used with R Radiators

K45 Offset Bolt – Carriage Bolt used at each weld nut at the bottom of the Radiator for leveling with the wall |

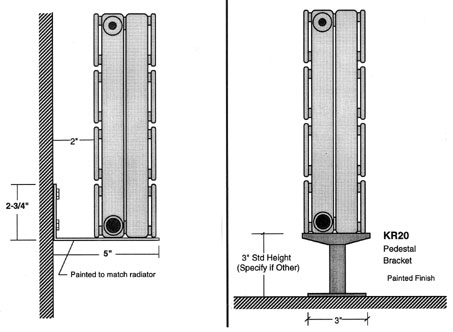

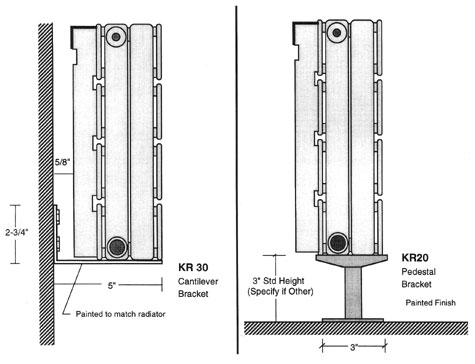

Floor Mounting

Model Type VLX-VX

Floor Mounting

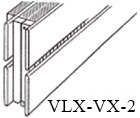

| VLX-VX Models: VLX-VX-1, VLX-VX-2, VLX-VX-3 and VLX-VX-4 only (back view) |

|

|

For Radiators |

20″ to 60″ Long – Use 2 KR30 or KR20 Brackets, one within 12 inches of each end. |

|

|

62″ to 138″ Long – Use 3 KR30 or KR20 Brackets, one at each end, one at the center |

|

|

140″ to 236″ Long – Use 4 KR30 or KR20 Brackets, one at each end, two distributed evenly in the middle |

| 238″ to 296″ Long – Use 5 KR30 or KR20 Brackets, one at each end, three distributed evenly in the middle | |

| 298″ to 354″ Long – Use 6 KR30 or KR20 Brackets, one at each end, four distributed evenly in the middle |

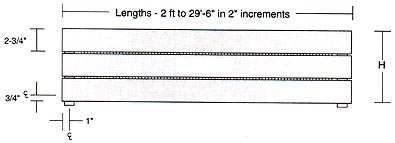

High Output Radiators: Model Type VLX-2

Heating Capacity

Model Type VLX-2

BTUH/ft Ratings

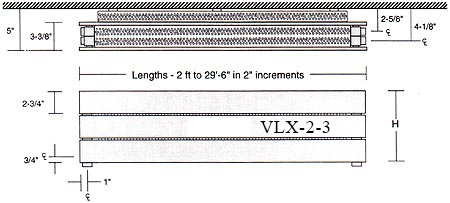

VLX-2-3 with Both Side & Vertical Connections – Shown for Example Only

Technical Data For All VLX-2 Models Is Included Below

| MODEL TYPE |

HEIGHT H |

BTUH/FT OUTPUT @ LISTED AWT & 65°F EAT | DRY WT lbs/ft |

||||||||

| 215°F | 190 | 180 | 170 | 160 | 150 | 140 | 130 | 120 | |||

|

VLX 7/7 – 2 |

2-3/4″ | 1299 | 1020 | 914 | 812 | 713 | 616 | 523 | 434 | 349 | 4.3 |

|

VLX 14/14 – 2 |

5-3/4″ | 2014 | 1581 | 1418 | 1258 | 1105 | 955 | 811 | 673 | 541 | 8.0 |

|

VLX 21/21 – 2 |

8-5/8″ | 2572 | 2018 | 1810 | 1607 | 1411 | 1220 | 1036 | 860 | 691 | 11.7 |

|

VLX 28/28 – 2 |

11-1/2″ | 3082 | 2418 | 2169 | 1925 | 1690 | 1462 | 1241 | 1030 | 828 | 16.4 |

|

VLX 35/35 – 2 |

14-3/8″ | 3788 | 2973 | 2666 | 2367 | 2078 | 1797 | 1526 | 1266 | 1017 | 19.6 |

|

VLX 42/42 – 2 |

17-1/4″ | 4263 | 3345 | 3000 | 2663 | 2338 | 2022 | 1717 | 1425 | 1145 | 23.2 |

|

VLX 49/49 – 2 |

20-1/4″ | 4738 | 3718 | 3335 | 2960 | 2599 | 2247 | 1909 | 1584 | 1273 | 27.4 |

|

VLX 56/56 – 2 |

23-1/8″ | 5200 | 4080 | 3660 | 3248 | 2852 | 2466 | 2095 | 1738 | 1396 | 32.5 |

|

VLX 63/56 – 2 |

26-1/8″ | 5451 | 4278 | 3836 | 3405 | 2990 | 2585 | 2196 | 1822 | 1464 | 34.7 |

|

VLX 70/56 – 2 |

29″ | 5691 | 4466 | 4005 | 3556 | 3122 | 2699 | 2293 | 1902 | 1528 | 36.9 |

NOTE: Heat Outputs for various AWT’s include 15% Heat Effect for placement along outside walls. Use the 215° F Output Rating with the Correction Factor for more specific design conditions. High Pressure increases Dry Weight by 15%

Correction Factors

Correction Factors

| EAT | |||||||||||

| AWT | 45°F | 50°F | 55°F | 60°F | 65°F | 70°F | 75°F | 80°F | 85°F | 90°F | 95°F |

| 240°F | 1.365 | 1.350 | 1.304 | 1.266 | 1.220 | 1.171 | 1.124 | 1.086 | 1.039 | 1 | 0.953 |

| 235°F | 1.343 | 1.305 | 1.267 | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 |

| 230°F | 1.305 | 1.267 | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 |

| 225°F | 1.267 | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 |

| 220°F | 1.219 | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 |

| 215°F | 1.171 | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 |

| 210°F | 1.124 | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 |

| 205°F | 1.086 | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 |

| 200°F | 1.038 | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 |

| 195°F | 1 | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 |

| 190°F | 0.952 | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 |

| 185°F | 0.910 | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 |

| 180°F | 0.868 | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 |

| 175°F | 0.826 | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 |

| 170°F | 0.785 | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 |

| 165°F | 0.744 | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 |

| 160°F | 0.704 | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 |

| 155°F | 0.664 | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 |

| 150°F | 0.625 | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 |

| 145°F | 0.587 | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 |

| 140°F | 0.549 | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 |

| 135°F | 0.511 | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 |

| 130°F | 0.474 | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 |

| 125°F | 0.438 | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 |

| 120°F | 0.403 | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 |

| 115°F | 0.369 | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 |

| 110°F | 0.334 | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 | 0.50 |

| 105°F | 0.301 | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 | 0.50 | 0.030 |

| 100°F | 0.269 | 0.237 | 0.207 | 0.177 | 0.149 | 0.122 | 0.096 | 0.071 | 0.50 | 0.030 | 0.011 |

| EXAMPLE: | To find the BTUH/ft Rating for an RF-4 Panel at 145°F AWT and 65°F EAT, Multiply the Correction Factor (0.438) by the BTUH/ft Rating at 215°F (1351), e.g. (0.438) X (1351) = 592 BTUH/ft |

Flow Rates

How To Determine Flow Rates

The flow rate through a Runtal radiator (or series of radiators) is dependent on the length of the radiator (or combined length of the radiator series), and the design Entering Water Temperature (EWT) and the design Leaving Water Temperature (LWT).

The designer picks the design EWT and LWT. For example, he might pick 170°F as the EWT and 150°F as the LWT. The median point between these two temperatures is called the Average Water Temperature (AWT), and in this example the AWT is 160°F.

The Runtal Heating Capacity charts are based on the heating capacity per foot of radiator, based on the designer’s chosen AWT, and this heating capacity per foot is expressed in units of BTUH/FT @ a given AWT. The required flow rate (GPM) is figured as follows:

Flow Rate = (Heating Capacity/Foot X Radiator Length)

DT –LWT) X 500]

The (EWT – LWT) is commonly referred to as the “Delta T”, or “DT”.

Therefore, our Flow Rate formula becomes:

GPM = (BTUH/FT X FT of Radiator) DT (DT X 500)

As an example, let’s say our designer needs 445 BTUH/FT capacity, over a

10′-0″ span of wall, and has chosen the design water temperatures as EWT = 170°F, and LWT = 150°F. This means our AWT is 160°F. Looking in the Runtal type “R” radiator Heating Capacity chart, we see that an R-4 radiator gives us the required 445 BTUH/FT at 160°F AWT. Therefore, the required flow rate for the 10′-0″ long R-4 radiator is:

GPM = (445 BTUH/FT X 10FT) DT (20°F DT X 500) = 0.445 GPM

Note that there are various combinations of EWT and LWT that can result in the same AWT. In our example above, for instance, a 180°F EWT and a 140°F LWT result in the same 160°F AWT. With Runtal’s unique flattened water tube design, Delta T’s of up to 60°F are possible without concern that the flow rate is too low for heat transfer (see the “Design Tips” section for more information).

As for a maximum flow rate for Runtal radiators, we recommend no more that 1.5 GPM per water tube. For our R-4 example above, this would mean a maximum flow rate of 6 GPM for an opposite end piped radiator, or 3 GPM for a same end piped radiator (see the “Design Tips” section for more information).

Piping Options

Piping Options

|

A Type Connections

|

B Type Connections

|

||||||||||

|

C Type Connections

|

D Type Connections

|

||||||||||

|

Opposite End Series

|

|||||||||||

|

Same End Series

|

|||||||||||

Specifications

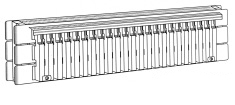

VLX 14/14 – 2 |

VLX-2 panel radiators are manufactured in the USA from cold rolled steel and consist of two panels with three sets of fins. The panels are finished in a gloss powdercoat, and are available in many standard colors and over 100 optional colors. These panels are made in lengths from 2’-0” to 29’- ”, and heights from 3” to 29”. Standard piping connections are 1/2” NPT for inlet and outlet piping, and 1/8” NPT for vents (3/4” NPT inlets and outlets are available by special order). For more complete VLX-2 specifications, please refer to the Runtal technical pages. |

BTUH/ft Ratings

| Energy efficient as well as space saving, VLX-2 panels are both radiant and convective. These panels provide more comfort at a lower room temperature than convective heaters. Various average water temperatures (AWT) are shown here for convenience, but for more specific conditions use the appropriate correction factor with the 215°F rating. Please see the technical pages for the correction factor best suited to the design conditions. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mounting Systems

VLX 21/21 – 2 |

Wall mounting with a continuous mounting system (brackets included) is standard on all VLX-2 panels. Free standing, cantilever and recessed wall mounting systems are also available. Please see the VLX-2 technical pages for more complete mounting details. |

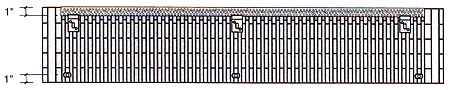

Wall Mounting

Model Type VLX-2

Wall Mounting

| VLX-2 Models (back view) |

|

|

For Radiators |

20″ to 60″ Long – Use 2 K12 Brackets, one at each end |

|

|

62″ to 138″ Long – Use 3 K12 Brackets, one at each end, one at the center |

|

|

140″ to 236″ Long – Use 4 K12 Brackets, one at each end, two distributed evenly in the middle |

| 238″ to 296″ Long – Use 5 K12 Brackets, one at each end, three distributed evenly in the middle | |

| 298″ to 354″ Long – Use 6 K12 Brackets, one at each end, four distributed evenly in the middle |

|

|

|

R clip – Mount to the Cutouts on the RF Radiator at the K12 Positions K12 Wall Bracket – Support Bracket used with RF Radiators

K45 Offset Bolt – Carriage Bolt used at each weld nut at the bottom of the Radiator for leveling with the wall |

Floor Mounting

Model Type VLX-2

Floor Mounting

| VLX-2 Models: VLX-2-1, VLX-2-2, VLX-2-3 and VLX-2-4 only (back view) |

|

|

For Radiators |

20″ to 60″ Long – Use 2 KR30 or KR20 Brackets, one within 12 inches of each end |

|

|

62″ to 138″ Long – Use 3 KR30 or KR20 Brackets, one at each end, one at the center |

|

|

140″ to 236″ Long – Use 4 KR30 or KR20 Brackets, one at each end, two distributed evenly in the middle |

| 238″ to 296″ Long – Use 5 KR30 or KR20 Brackets, one at each end, three distributed evenly in the middle | |

| 298″ to 354″ Long – Use 6 KR30 or KR20 Brackets, one at each end, four distributed evenly in the middle |

Hot Spring Radiators

Overview

|

|

|

|

|

Model: |

HOT 60 |

HOT 180 |

|

Heat Output: |

||

| Hydronic Heat Output @180°F |

1975* BTUH | 6681* BTUH |

| *chrome finish reduces radiator output by 20% | ||

| Pair of chrome angle shut-off valves included | ||

BTUH Calculations

Calculating BTUH Output for Different Water Temperatures

The BTUH outputs are listed for 180° water. The following chart may be used to calculate the BTUH outputs for different water temperatures:

| Water Temperature | Multiply the Listed BTUH output (180°) by: |

| 120° | 0.38 |

| 130° | 0.48 |

| 140° | 0.57 |

| 150° | 0.67 |

| 160° | 0.78 |

| 170° | 0.89 |

| 180° | 1 |

| 190° | 1.13 |

To size the radiators it is necessary to calculate a house’s heating requirement. This calculation measured in BTU/Hour should be done on a room-by-room basis either by a heating contractor or qualified plumber. The following are some estimates of Heat Requirements for Sample Cities:

| City: | BTUH per sq. foot: |

| Boston | 40 |

| Chicago | 40 |

| Denver | 40 |

| New York City | 40 |

| Philadelphia | 35 |

| Portland, OR | 25 |

| San Francisco | 25 |

| Seattle | 25 |

| Toronto | 40 |

| Washington, D.C. | 35 |

Colors & Finishes

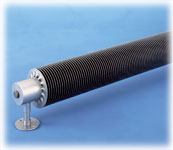

Flow Form Radiators

Overview

The industrial heating element appears as a beautiful object in its own right. Flow Form’s spiral fin, designed for technical efficiency, adds a dramatic twist to modern living.

BTUH Calculations

Calculating BTUH Output for Different Water Temperatures

The BTUH outputs are listed for 180° water. The following chart may be used to calculate the BTUH outputs for different water temperatures:

| Water Temperature | Multiply the Listed BTUH output (180°) by: |

| 120° | 0.38 |

| 130° | 0.48 |

| 140° | 0.57 |

| 150° | 0.67 |

| 160° | 0.78 |

| 170° | 0.89 |

| 180° | 1 |

| 190° | 1.13 |

To size the radiators it is necessary to calculate a house’s heating requirement. This calculation measured in BTU/Hour should be done on a room-by-room basis either by a heating contractor or qualified plumber. The following are some estimates of Heat Requirements for Sample Cities:

| City: | BTUH per sq. foot: |

| Boston | 40 |

| Chicago | 40 |

| Denver | 40 |

| New York City | 40 |

| Philadelphia | 35 |

| Portland, OR | 25 |

| San Francisco | 25 |

| Seattle | 25 |

| Toronto | 40 |

| Washington, D.C. | 35 |

Colors & Finishes

Design & Planning

Runtal heating products can blend into a traditional décor, highlight an ultra-modern design, or accent any style in between. From baseboard style, to wall panels, to fancy curves and dramatic room dividers, Runtal manufactures the perfect welded steel radiator for every application. Since Runtal manufactures an almost unlimited selection of sizes, colors, and heat outputs. Runtal is truly a designer’s dream. Innovation in architectural detail is no longer held hostage to “old rules” of mechanical heating systems. Imagine the possibilities, confident that the final design will be comfortable and stylish.

Store

Purchase any of our handcrafted stocked Runtal White radiators directly from the factory, for quick delivery, or choose from a variety of 9 standard colors for 2-week delivery.

Design Assistance & Custom Products

Runtal Radiators can be custom designed to fit your exact specifications. Choose from an endless variety of colors, including select metallic finishes. Our experts will assist you with finding the exact size, heat capacity and décor your are looking for.