Residential Hydronic

Baseboard radiators

Overview

Runtal’s Baseboard style is ideal for those desiring a sleek low profile perimeter heating solution. Like all of our products, our baseboard is designed to last, crafted from heavy gauge fully welded steel. Finished with an electrostatically applied, baked on powder coat paint, your purchase will look as good years down the road as it does the first day you install it. All Runtal Radiators are finished with an electrostatically applied baked-on powder coat finish ensuring beauty meets durability. As a retrofit, Runtal baseboard is a natural replacement for fin-tube or cast iron. Depending upon your required heat output, or the desired design “look,” Runtal standard baseboard is available in three different heights and lengths from 2′ to 14′. For design ideas and tips please visit our Design and Planning section found at the bottom of this page.

standard product in stock

We stock all sizes of our standard baseboard for quick delivery in our most popular color, Runtal White. The other 9 standard colors can be delivered within 2 weeks. Runtal Hydronic Baseboard is offered in three heights (6”, 9”, 12”) and lengths from 2’ to 3.5′ in six inch increments and 4′ to 14’ in 1foot increments. Visit our online shop or give us a call. It’s that easy.

If our expansive stocked standard product line or color pallet do not fit your exact design requirements, please see our Design Assistance and Custom Products section for Made-To-Order radiators. Our sales /applications experts are ready to help craft a custom solution just for you.

Simple to install

Uniform fittings allow each radiator to be piped eight different ways with connections located on the side and bottom of both ends of the radiator, with air vents on both sides. Simply select the piping configuration which fits your application for inlet, outlet and venting. Continuous Mounting eliminates the need for backing. Simply wall mount (hardware included). All pipe fittings are 1/2” NPT with 1/8” NPT Vent Fittings (Manual Vent Included!). Standard Pipe Covers are also in stock.

Versatile

Whether it’s a one radiator renovation, or a whole house, Runtal has the perfect solution, and can be used as a direct replacement for fin-tube or cast iron baseboard (see tips on installation), or it may be used with water temperatures as low as 140° F , (making it a perfect alternative or complement to floor heating). Runtal is attractive, durable, healthy, and comfortable. Runtal Radiators carry a 5-year warranty.

Specifications

|

|

|||

| Model: Height: Heat Output: per Foot* (Based on 180°F average water temperature) |

UF-2 6″ 600 BTUH/ft.* |

UF-3 9″ 770 BTUH/ft.* |

UF-4 12″ 930 BTUH/ft.* |

| Length & Heat Output: |

| 2 ft. | 1,200 | 1,540 | 1,860 |

| 2.5 ft | 1,500 | 1,925 | 2,325 |

| 3 ft. | 1,800 | 2,310 | 2,790 |

| 3.5 ft | 2,100 | 2,695 | 3,255 |

| 4 ft. | 2,400 | 3,080 | 3,720 |

| 5 ft. | 3,000 | 3,850 | 4,650 |

| 6 ft. | 3,600 | 4,620 | 5,580 |

| 7 ft. | 4,200 | 5,390 | 6,510 |

| 8 ft. | 4,800 | 6,160 | 7,440 |

| 9 ft. | 5,400 | 6,930 | 8,370 |

| 10 ft. | 6,000 | 7,700 | 9,300 |

| 11 ft. | 6,600 | 8,470 | 10,230 |

| 12 ft. | 7,200 | 9,240 | 11,160 |

| 13 ft. | 7,800 | 10,010 | 12,090 |

| 14 ft. | 8,400 | 10,780 | 13,020 |

Installation Tips for Runtal Baseboard/Wallpanels

|

Roughing In: The rough in dimensions are the same for all 5 heights. |

|

|

Tips:

|

|

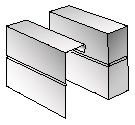

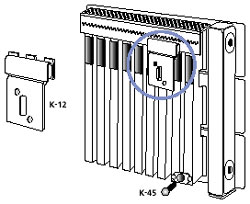

Mounting: The mounting system is identical on all 5 heights. |

|

Tips:

|

|

Piping: Each radiator may be piped eight different ways. |

|

Tips:

|

|

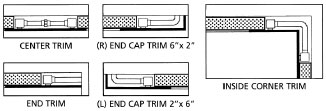

Trim Covers: There are 2 types of standard trim covers: |

Vertical Covers: These come standard in 3” and 10” heights and are designed to cover straight vertical pipe between the radiator and the floor. They can be easily field cut for heights other than 3” and 10”.Horizontal Covers: Standard trims simply snap into place. Straight Trims (used as End Trims & Center Trims) are 12” long. Inside Corners are 12” x 12” and End Cap Trims are either 6” x 2” (right hand) or 2” x 6” (left hand). Outside Corner Trims and other special trims are readily available on request.

|

|

Tips:

|

|

System: Runtal will work well in both High and Low temperature closed loop systems. |

|

Tips:

|

Baseboard and Wall Panel Radiators Brochure (PDF)

Operation & Maintenance

Hydronic Radiator Operation

- Radiators are manufactured in the USA of cold rolled low carbon steel and should be used only in closed closed hydronic systems to assure no corrosion of any system components.

- Proper radiator operation depends on adequate flow of water to the panel, which can only be accomplished when all the system air has been fully vented from the panels.

- Radiators should each be vented, with the system pressurized but in a static state (pumps off). Venting may need to be done periodically to assure a closed system.

- DO NOT OVER-PRESSURIZE RADIATORS:

Most radiators are standard pressure construction. Standard pressure radiators should be tested with NO MORE THAN 50 PSI. - Radiator Operating Pressure Ratings:

Standard Pressure – 56 psi max (Tested at 74 psi)

High Pressure – 128 psi max (Tested at 184 psi) - Radiators expand a maximum of 0.016 inch per linear foot of length if heated to 215°F. Piping attached to the radiator must provide the necessary expansion compensation.

- Flexible piping and elbowed piping are two simple ways to provide the 1/8 inch to 1/2 inch (typical) of flexibility required in expansion situations (usually series piping).

- Runtal Radiators require less flow rate than other hydronic heating products. If flow noise is apparent, balance the system until the noise is reduced.

- For a delta T of 20°F. (T supply minus T return), divide the total Btu/hr capacity of the loop by 10,000. This gives the Flow Rate in gallons per minute (GPM)

- Many levels of control are available today for hydronic systems. Runtal Radiators will provide nice, even heating whether operated by a simple thermostat to baseboard loop system, or an advanced boiler reset controller with motorized mixing valves, constant circulation and 2-pipe distribution.

Radiator Maintenance

- Hydronic system maintenance should include routine checks for piping leaks (usually indicated by frequent makeup water), and a yearly diagnosis of the system water pH to evaluate its corrosive potential.

- Internal radiator maintenance depends entirely on the system water makeup and proper venting. Hydronic system additives are available to passivate and protect against freezing. These additives will not significantly reduce the output of Runtal Radiators.

- External radiator maintenance consists of keeping the surfaces clean, and any paint nicks or deep scratches painted with touch-up to prevent any surface rust.

- Radiators can be painted after sanding with fine grit paper to dull the high gloss and by wiping with solvent or a tack rag. Use only oil-based enamel paint (alkyd, acrylic, urethane, epoxy) – do not use latex or lacquer paint. Use urethane or epoxy enamel for radiators located in harsh environments. Spray the paint to achieve an even coating, and let dry completely before heating the radiator.

Design & Color Options

With a vibrant and varied palette, you can choose a shade that will blend into the background or add an eye-catching focal point to your room. Whether you’re decorating a neutral space, or you’re eager to inject character and color, there’s an ideal match for you.

You can choose from a range of standard colors or pay a little extra for a custom shade for your home. For custom color options please visit our Design Assistance and Custom Products Section where our team can help you find the exact match you are looking for.

Specifications

Operation & Maintenance

Hydronic Radiator Operation

- Radiators are manufactured in the USA of cold rolled low carbon steel and should be used only in closed closed hydronic systems to assure no corrosion of any system components.

- Proper radiator operation depends on adequate flow of water to the panel, which can only be accomplished when all the system air has been fully vented from the panels.

- Radiators should each be vented, with the system pressurized but in a static state (pumps off). Venting may need to be done periodically to assure a closed system.

- DO NOT OVER-PRESSURIZE RADIATORS:

Most radiators are standard pressure construction. Standard pressure radiators should be tested with NO MORE THAN 50 PSI. - Radiator Operating Pressure Ratings:

Standard Pressure – 56 psi max (Tested at 74 psi)

High Pressure – 128 psi max (Tested at 184 psi) - Radiators expand a maximum of 0.016 inch per linear foot of length if heated to 215°F. Piping attached to the radiator must provide the necessary expansion compensation.

- Flexible piping and elbowed piping are two simple ways to provide the 1/8 inch to 1/2 inch (typical) of flexibility required in expansion situations (usually series piping).

- Runtal Radiators require less flow rate than other hydronic heating products. If flow noise is apparent, balance the system until the noise is reduced.

- For a delta T of 20°F. (T supply minus T return), divide the total Btu/hr capacity of the loop by 10,000. This gives the Flow Rate in gallons per minute (GPM)

- Many levels of control are available today for hydronic systems. Runtal Radiators will provide nice, even heating whether operated by a simple thermostat to baseboard loop system, or an advanced boiler reset controller with motorized mixing valves, constant circulation and 2-pipe distribution.

Radiator Maintenance

- Hydronic system maintenance should include routine checks for piping leaks (usually indicated by frequent makeup water), and a yearly diagnosis of the system water pH to evaluate its corrosive potential.

- Internal radiator maintenance depends entirely on the system water makeup and proper venting. Hydronic system additives are available to passivate and protect against freezing. These additives will not significantly reduce the output of Runtal Radiators.

- External radiator maintenance consists of keeping the surfaces clean, and any paint nicks or deep scratches painted with touch-up to prevent any surface rust.

- Radiators can be painted after sanding with fine grit paper to dull the high gloss and by wiping with solvent or a tack rag. Use only oil-based enamel paint (alkyd, acrylic, urethane, epoxy) – do not use latex or lacquer paint. Use urethane or epoxy enamel for radiators located in harsh environments. Spray the paint to achieve an even coating, and let dry completely before heating the radiator.

Design & Color Options

With a vibrant and varied palette, you can choose a shade that will blend into the background or add an eye-catching focal point to your room. Whether you’re decorating a neutral space, or you’re eager to inject character and color, there’s an ideal match for you.

You can choose from a range of standard colors or pay a little extra for a custom shade for your home. For custom color options please visit our Design Assistance and Custom Products Section where our team can help you find the exact match you are looking for.

Design & Planning

Runtal heating products can blend into a traditional décor, highlight an ultra-modern design, or accent any style in between. From baseboard style, to wall panels, to fancy curves and dramatic room dividers, Runtal manufactures the perfect welded steel radiator for every application. Since Runtal manufactures an almost unlimited selection of sizes, colors, and heat outputs. Runtal is truly a designer’s dream. Innovation in architectural detail is no longer held hostage to “old rules” of mechanical heating systems. Imagine the possibilities, confident that the final design will be comfortable and stylish.

Store

Purchase any of our handcrafted stocked Runtal White radiators directly from the factory, for quick delivery, or choose from a variety of 9 standard colors for 2-week delivery.

Design Assistance & Custom Products

Runtal Radiators can be custom designed to fit your exact specifications. Choose from an endless variety of colors, including select metallic finishes. Our experts will assist you with finding the exact size, heat capacity and décor your are looking for.